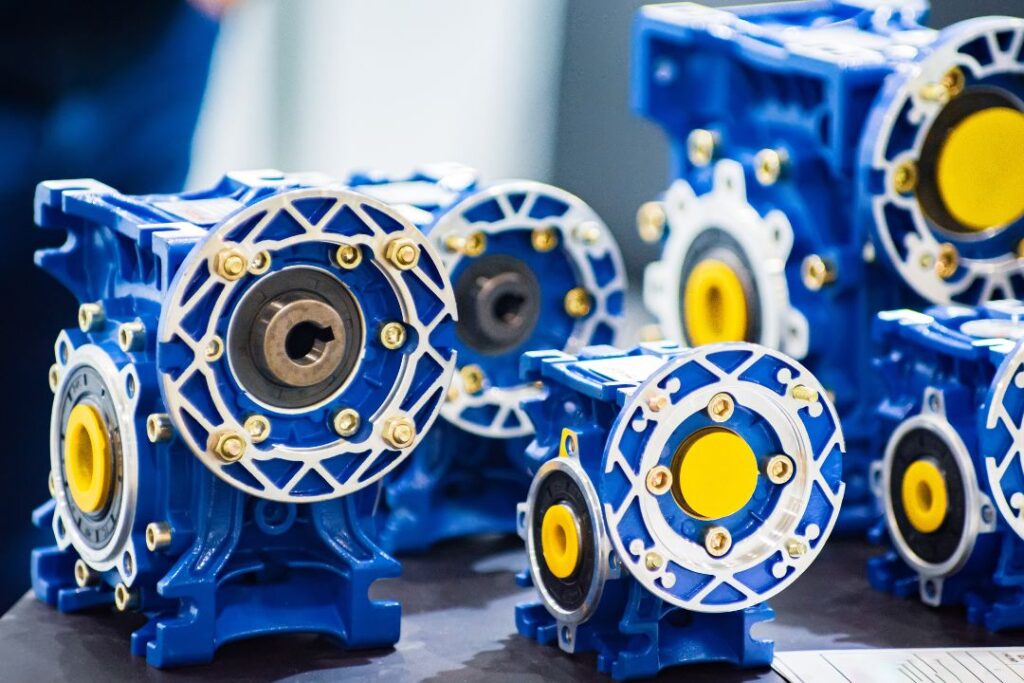

Shaft-mounted speed reducers are versatile components used in various industrial applications to optimize the performance and efficiency of machinery. By attaching directly to the driven shaft of equipment, they simplify the transmission of power and aid in reducing the speed and increasing the torque of the output, which is essential for heavy machinery operation. These compact and efficient reducers are ideal for conveyors, crushers, and mixers, among other equipment that require durable and reliable speed control solutions.

Conveyor Systems

Conveyor systems are perhaps the most common application for shaft-mounted speed reducers. These reducers allow for precise control of conveyor speed, ensuring materials are transported at the desired pace, minimizing the risk of product damage, and maximizing efficiency. Shaft-mounted speed reducers contribute to maintaining consistent speed and torque, which is crucial for handling variable loads on conveyor belts. Additionally, their compact and sturdy design supports the heavy-duty needs of industry-specific conveyor applications. This results in reduced downtime and maintenance costs, as well as prolonged equipment lifespan, making them an indispensable component in logistics, food processing, and material handling industries.

Mixers and Agitators

Mixers and agitators benefit greatly from the use of shaft-mounted speed reducers, which ensure optimal mixing speeds and torque levels necessary for effective processing. These reducers are essential in industries such as food production, pharmaceuticals, and chemical manufacturing, where precise control over mixing intensity and duration is required. By providing consistent performance and reducing motor stress, shaft-mounted speed reducers enhance the overall efficiency and reliability of mixing operations. Their straightforward installation and low maintenance requirements make them particularly advantageous for continuous processing environments, where minimizing downtime is a critical factor.

Material Handling Equipment

Material handling equipment often incorporates shaft-mounted speed reducers to improve operational efficiency and reliability. These machines, including hoists, winches, and lifts, rely on precise speed control to handle loads smoothly and safely. By mitigating the wear on motors and providing consistent torque, shaft-mounted speed reducers help extend the life of the equipment. Their robust construction supports the demanding needs of various industrial environments, reducing the likelihood of breakdowns. Furthermore, their easy installation and maintenance contribute to minimizing operational disruptions, making them integral to optimizing processes in warehouses, construction sites, and manufacturing facilities.

Pumps and Fans

Pumps and fans are vital components in numerous industrial and environmental control applications, and the use of shaft-mounted speed reducers can greatly enhance their performance. These reducers play an essential role in regulating the rotational speed, ensuring that pumps and fans operate at optimal efficiency without overloading motors. By delivering precise speed control and consistent torque, they help manage the flow rate and pressure in pumps used for water treatment, chemical processing, and HVAC systems. The robust design of shaft-mounted speed reducers ensures durability and reliability in demanding environments, minimizing maintenance needs and prolonging the lifespan of both pumps and fans.

Understanding the common applications for shaft-mounted speed reducers is vital for selecting the appropriate type and size for specific industrial needs. By providing reliable speed control, reducing motor stress, and increasing equipment efficiency, these reducers play a crucial role in optimizing processes across various industries. Furthermore, fully understanding your equipment can help you when your shaft-mounted speed reducer isn’t working or related complications.